Industrial Services

Wafaq is a leading contractor providing several industrial services to the Oil & Gas, Petrochemical, Metal and Mineral, Power and Water and other heavy industrial plant facilities in the Kingdom of Saudi Arabia. Our support services meet the needs of all industrial companies involved in manufacturing requiring local Saudi and international talent.

Industrial services encompass a wide range of support activities crucial for maintaining and optimizing industrial operations. These

services are essential for ensuring the efficiency, safety, and productivity of industrial facilities. Key aspects of industrial services.

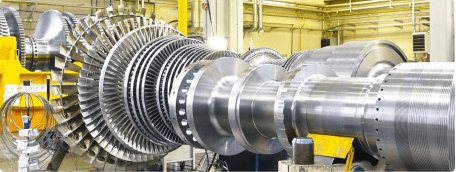

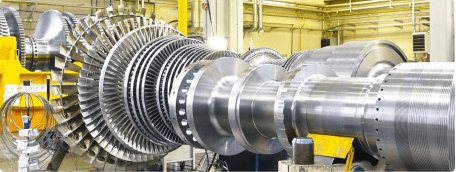

Mechanical

Mechanical service involves the maintenance, repair, and servicing of machinery and equipment to ensure their proper functioning and longevity. This includes routine inspections, diagnostics, and troubleshooting to prevent breakdowns and optimize performance. Mechanical service technicians work with various systems, such as HVAC, engines, and industrial machinery, across different industries. Regular mechanical service is essential for minimizing downtime, enhancing safety, and extending equipment lifespan.

E & I Industrial

Electrical and industrial services encompass the installation, maintenance, and repair of electrical systems and equipment used in industrial settings. These services ensure the safe and efficient operation of electrical infrastructure, including wiring, motors, control systems, and power distribution. Technicians perform regular inspections, troubleshooting, and upgrades to meet industry standards and compliance regulations. By maintaining reliable electrical systems, these services help optimize industrial operations and minimize production downtime.

General Maintenance

General maintenance is essential for ensuring the optimal

performance, safety, and longevity of equipment, machinery,

and facilities. It involves routine tasks and preventive measures

to keep systems functioning efficiently and to prevent unexpected

breakdowns. Here’s a comprehensive overview of general

maintenance:

Shutdown & Turnaround

Shutdowns and turnarounds are critical processes in industrial

operations, often associated with planned maintenance,

inspection,and overhaul activities.

Technical Site Support

Wafaq has a team of more than 1,000 employees working

with various clients in Technical Site Support services. We

have provided continuous service to some of our key clients

which is testament to the commitment of

Wafaq in delivering the best in class resources.

Fabrication

Fabrication refers to the process of constructing products by cutting, bending, and assembling raw materials, typically metals. This process is essential in various industries, including automotive, aerospace, and construction, where precise and durable components are necessary. Modern fabrication techniques often utilize advanced technologies such as computer numerical control (CNC) machines and robotic welding to enhance accuracy and efficiency.

Process Engineering

Process engineering is a branch of engineering that focuses on the design, operation, control, and optimization of industrial processes. It involves applying principles of chemistry, physics, and engineering to develop efficient processes for converting raw materials into valuable products. Process engineers work to improve safety, sustainability, and cost-effectiveness in industries such as chemical, petrochemical, pharmaceuticals, and food production. They utilize techniques like process simulation and analysis to enhance process efficiency and product quality.

SIMULATION & MODELLING SERVICES

Simulation & Modelling Services focused on process industries. These services include using advanced tools like Aspen HYSYS and Aspen Flare Analyzer for tasks such as Flare System Adequacy Checks, PSV Sizing & Validation, refinery reactor modeling, and dynamic simulations. Additionally, they provide digital twin implementation, process optimization, and energy optimization, ensuring efficient and safe plant operations through rigorous simulation practices.

REVAMPING & UPGRADING (MOC)

Revamping and upgrading industrial facilities, also known as Management

of Change (MOC), are critical processes that ensure the continuous

improvement, safety, and efficiency of operations. These processes

involve making significant changes to equipment, processes, or systems

to enhance performance, comply with regulations, or meet new operational

requirements.

Training

Training is the process of developing skills, knowledge, and competencies in individuals to enhance their performance in a specific area. It can be conducted in various settings, such as workplaces, schools, or online platforms, and may include hands-on practice, workshops, and theoretical instruction. Effective training programs are tailored to the needs of participants and often involve assessment to measure progress. The ultimate goal is to empower individuals to perform tasks more efficiently and confidently.

Chemical Cleaning

Chemical cleaning removes rust, scale, grease, and other contaminants from industrial equipment and pipelines.

It improves efficiency, prevents corrosion, and extends the lifespan of machinery.

Ideal for boilers, heat exchangers, and tanks across various industries.

We use safe, customized chemical solutions for effective, non-invasive cleaning.

Our expert team ensures minimal downtime with maximum performance results.

Mechanical Services

E & I Industrial

General Maintenance

Shutdown & Turnaround

Technical Site Support

Fabrication

Process Engineering

Simulation

REVAMPING & UPGRADING (MOC)

Training

Chemical Cleaning